Automobiles/auto parts

Automotive

Reduce product defects and increase productivity of auto parts

The production of automobiles and parts involves important processes such as applying sealants and adhesives, and filling with grease.

This process requires highly precise, accurate, and stable liquid application.

-

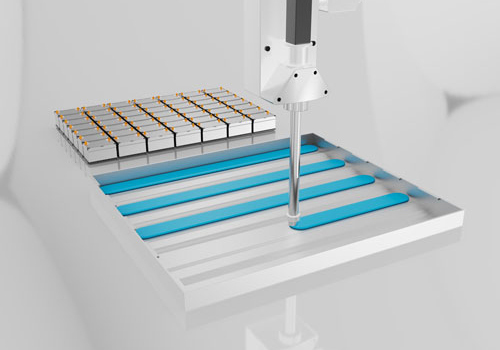

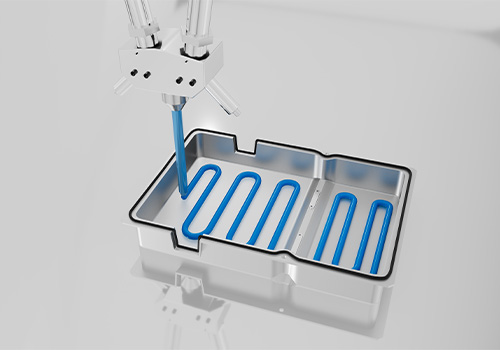

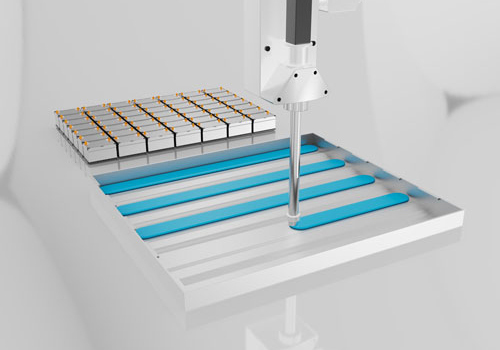

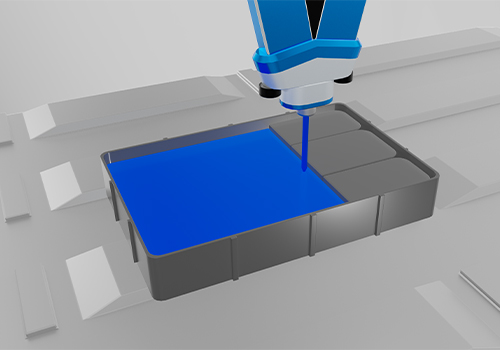

battery

Application type: Line application

Liquid used: Thermal paste

Work: battery module

-

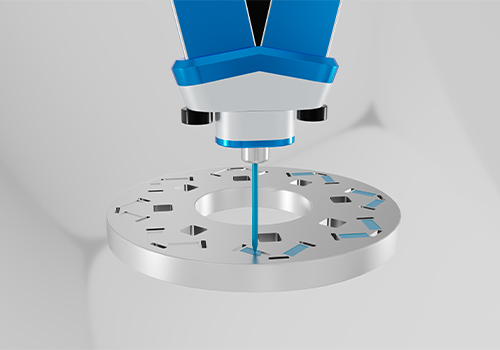

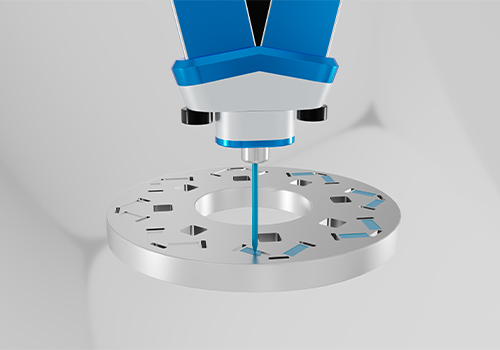

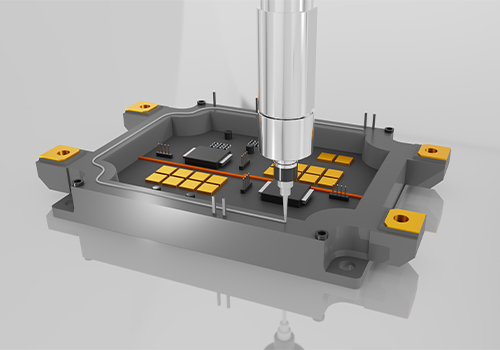

Motor

Application type: potting

Liquid used: 2-component material

Work: Electric motor magnet

-

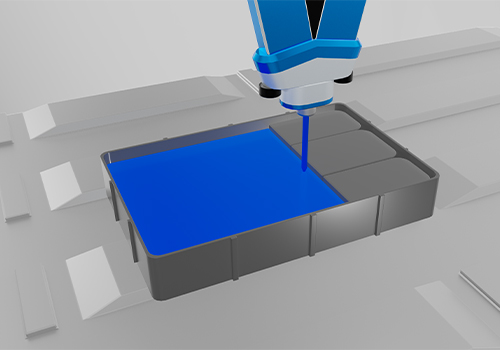

Auto parts

Application type: Filling

Liquid used: Epoxy resin

Work: control box

-

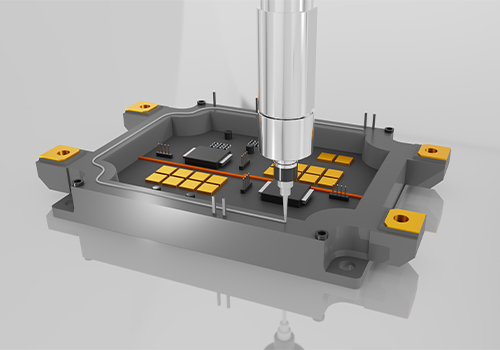

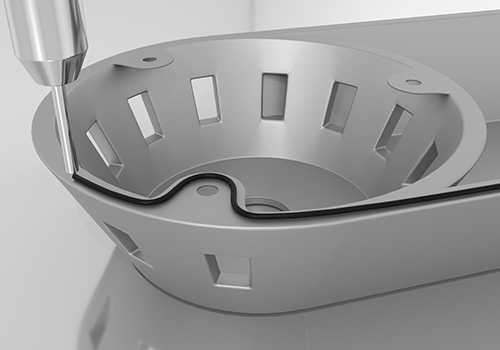

inverter

Application type: Line application

Liquid used: Liquid gasket

problem

- A problem occurred where the coating material was scattered in areas other than the areas where it should be applied. In addition, bulges were observed at the starting and ending points of coating, and there were some areas where the film thickness was not uniform.

- When applying moisture-proof coating materials to substrates, problems such as air bubbles and dripping from the edges of the substrates occurred, making the quality unstable.

Benefits

- We were able to achieve a stable coating trajectory without scattering and avoid areas where coating is not permitted. In addition, stable coating improved bulges at the start and end of coating and unevenness in film thickness.

- Precise coating greatly reduces the occurrence of bubbles. Because the coating effect is uniform, the protection and reliability of parts has been improved.

Introduced products

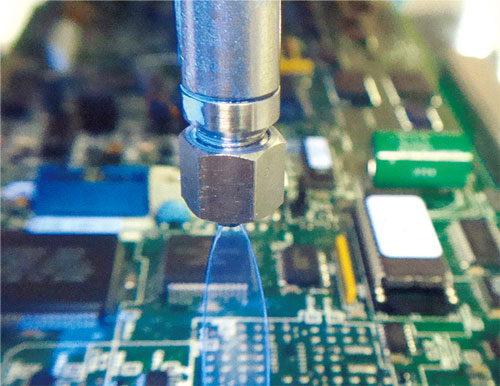

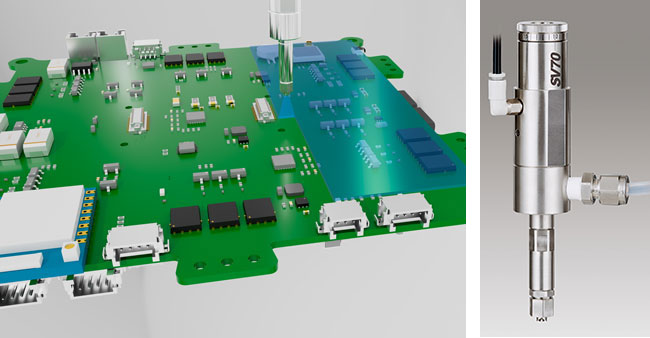

Conformal coating valve SV70

The SV70 conformal coating valve enables fast and consistent vapor retarder application.

Square nozzle allows for excellent dispensing patterns

- Rectangular nozzle diameter reduces liquid clogging

- Capable of applying wide (10mm) coatings at high speed

- Spatter-free coating application

- There is no uneven coating at the start and end points, and straight line coating with sharp edges is possible.

- High-speed response allows for easy liquid dispensing

Conformal coating machine AXELIA AXSC500

Optimal coating can be achieved with easy operation

Inline type coating machine

- Sensory teaching with Fluid magic for coating

- Equipped with 3WAY-SKY camera (compatible with teaching, position correction, and inspection)

- Can be equipped with high precision coating valve SV70

- Equipped with a coating width confirmation sensor to achieve accurate coating width.

- Flexible application operation is possible with 5-axis drive including tilt and rotation.

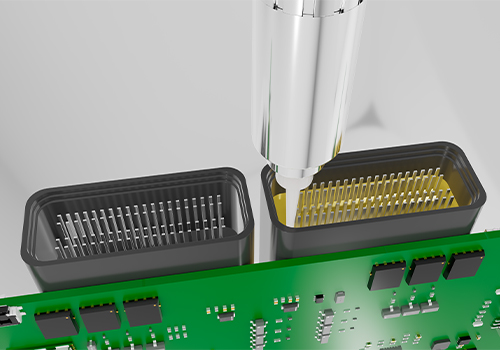

problem

- When potting to protect and insulate the terminals of the ECU and protect the terminals from vibration and external influences, bubbles were generated during the process of injecting the liquid.

- If uniformity of application was not ensured, the liquid could not spread evenly over the part surface, resulting in a layer of uneven thickness or density.

Benefits

- The stable discharge is unaffected by pressure, temperature, and time, which reduces the generation of air bubbles and improves sealing and insulation properties during potting work.

- Consistent, high-precision coating work was possible while mixing the two liquids with a fixed amount within ±2%, and quality stability was maintained.

Introduced products

preeflow® eco-DUO330/450/600

The preeflow® eco-DUO series, a two-liquid positive displacement high-precision microdispenser, is a motor-driven high-precision dispenser that can mix and dispense two liquids at a constant rate within ±2% via a rotor and stator. Mixing is performed after increasing the quantitative properties of each liquid to achieve accurate mixing ratio and discharge volume.

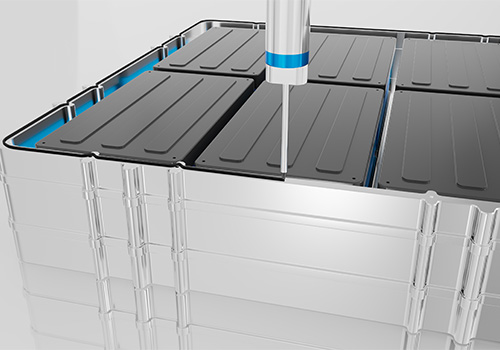

problem

- A liquid gasket is applied to protect the inside of a battery, and it was difficult to maintain a uniform coating width and thickness.

- The amount of coating was not stable, product defects due to stringing occurred frequently, and production efficiency was poor due to correction work.

Benefits

- With the introduction of the vipro-PUMP series, it has become possible to ensure uniform width and thickness when applying liquid gaskets through precise control.

- The coating amount has been stabilized, product defects due to stringing have been significantly reduced, the frequency of correction work has been reduced, and product quality and production efficiency have been improved.

Introduced products

vipro-PUMP series dispenser (large capacity type)

- Positive displacement type achieves a discharge accuracy of ±1% (at 1° per rotation)

- Highly accurate application of high viscosity liquids and filler-containing liquids

- Applicable to high viscosity liquids of up to 7,000.000 mPa・s (cps)

- Continuous quantitative application of liquids that are susceptible to shearing forces, filler-containing liquids, abrasive liquids, etc.

problem

In order to obtain the optimal heat dissipation characteristics for EV battery units, the heat dissipation material applied has a high proportion of inorganic filler, which tends to cause wear. Parts had to be replaced frequently due to wear.

Benefits

The durability of ceramic rotors has significantly reduced the frequency with which rotors and stators need to be replaced. This reduces the frequency of maintenance and reduces replacement costs and downtime.

Introduced products

vipro-PUMP series dispenser (large capacity type)

- Positive displacement type achieves a discharge accuracy of ±1% (at 1° per rotation)

- Highly accurate application of high viscosity liquids and filler-containing liquids

- Applicable to high viscosity liquids of up to 7,000.000 mPa・s (cps)

- Continuous quantitative application of liquids that are susceptible to shearing forces, filler-containing liquids, abrasive liquids, etc.

ceramic rotor

Very effective for coating abrasive materials that are difficult to coat.

It can solve the problem of material discoloration and rotor wear, and the system life can be expected to be significantly extended.

problem

- When applying line coating, it is necessary to maintain an appropriate coating thickness on parts with complex shapes, but it has been difficult to ensure uniform coating.

- The amount of coating was not stable, product defects due to stringing occurred frequently, and rework was routinely performed.

Benefits

- With the introduction of the vipro-PUMP series, it has become possible to ensure an appropriate coating thickness even on parts with complex shapes.

- The amount of liquid gasket applied was stabilized, product defects due to stringing were significantly reduced, the frequency of rework was reduced, and product quality and production efficiency were improved.

Introduced products

vipro-PUMP series dispenser (large capacity type)

- Achieves a discharge accuracy of ±1% with a positive displacement type (at 1° per rotation)

- Highly accurate application of high viscosity liquids and filler-containing liquids

- Applicable to high viscosity liquids of up to 7,000.000 mPa・s (cps)

- Continuous quantitative application of liquids that are susceptible to shearing forces, filler-containing liquids, abrasive liquids, etc.